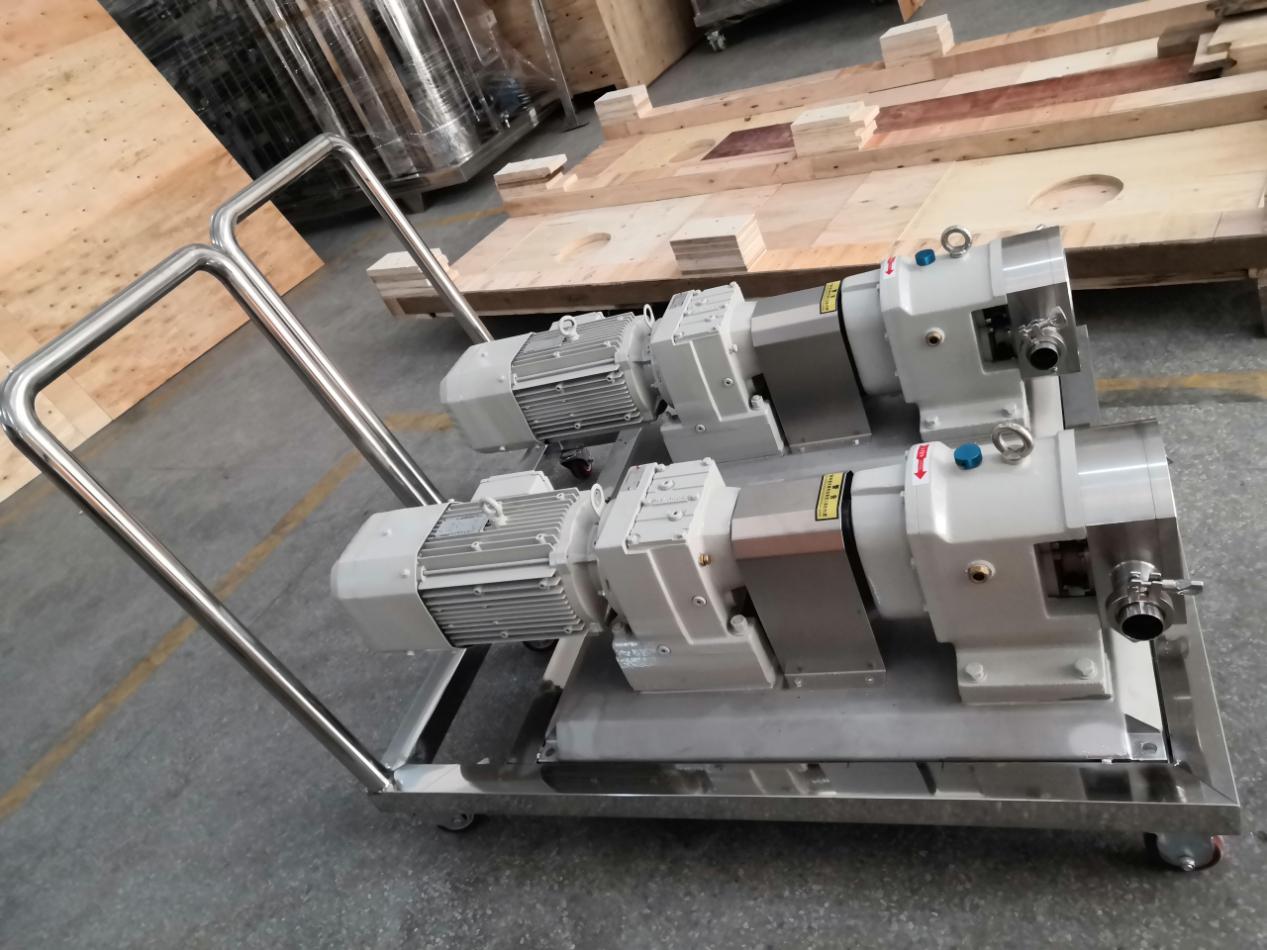

Transfer Pump (Rotary Pump & Rotary Pump & Screw Pump & Centrifugal Pump & Diagram Pump & Emulsifier/Homogenizer Pump)

Product Introduction

30 Years Of Experience;

3-7 days delivery, Reasonable Price And Best Service, CE Certificated Products;

Advanced Technology;

Rotor pump is also names rotary lobe pump, three-lobe pump, sole pump, etc. When the 2 simultltaneous reverse rotaing rotors (with 2-4 gears) revolve, it produces suction force at the inlet (vacuum), which intakes the material delivered.

Specifications: 3T-200T, 0.55KW-22KW

Material: The part contact with medium:AISI316L stainless steel

Other parts: AISI304 stainless steel

The sealing contact with medium: EPDM

Standards: DIN, SMS

Temperature range: -10℃--140℃(EPDM)

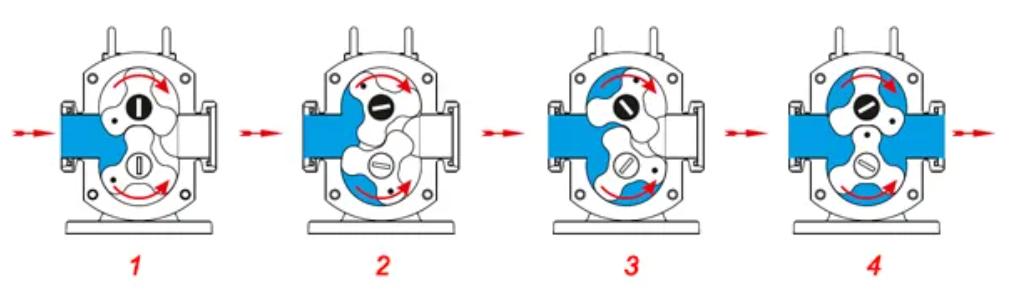

Working Principle of Rotary Lobe Pump

The rotary lobe pumps we also called them lobe rotor pumps. They are one popular transfer pump to conveying the food, beverage, pulp and paper, chemical, pharmaceutical and so on. The rotor lobe pump relies on two synchronously rotating rotors that generate suction (vacuum) at the inlet during the rotation. Thereby sucking in the material to be conveyed. Both rotors split the rotor chamber into different spaces. Then operate in the order of 1-2-3-4. The medium is delivered to the discharge port. In this cycle, the medium (material) is continuously transported out by the source.

Specification

| Flow(per 100 rotation) |

Suggested rotation speed(RPM) |

Capacity(L-H) | power(KW) |

| 3 | 200-500 | 300-800 | 0.55 |

| 6 | 200-500 | 650-1600 | 0.75 |

| 8 | 200-500 | 850-2160 | 1.5 |

| 12 | 200-500 | 1300-3200 | 2.2 |

| 20 | 20o-500 | 2100-5400 | 3 |

| 30 | 200-400 | 3200-6400 | 4 |

| 36 | 200-400 | 3800-7600 | 4 |

| 52 | 200-400 | 5600-11000 | 5.5 |

| 66 | 200-400 | 7100-14000 | 7.5 |

| 78 | 200-400 | 9000-18000 | 7.5 |

| 10o | 200-400 | 10000-22000 | 11 |

| 135 | 200-400 | 15000-30000 | 15 |

Type of Rotor and Stator

1.Single Lobed Rotor: More suitable for conveying media which containing large granular materials. The breaking rate of large granular materials is low. But on other hand it is not popular one for used, Because its pulsation is large and pressure is low, also the volume is small for the space of transferred materials.

2.Two-Lobed Rotor (Butterfly Rotor) More suitable for conveying media which containing small and medium-size granular materials. The breaking rate to these materials is low and getting slightly pulsating. The volume is a little less than three-lobed rotor for the space of transferred materials.

3.Three-Lobed Rotor It is widely used one rotor. The volume is bigger than other type of rotors for the space of transferred materials. Also each performance is higher than other rotors. Just it has a certain rate of breakage to the particulate materials on the transport way.

4.Multi-Lobed Rotor(4-12) The volume is more smaller for the space of transferred materials and breaking rate more higher when the quantity of rotary vane of rotor be increased, . Just the transport way more stable.

Character

1,There Is A Certain Gap Between Rotor And Rotor, No Friction Coefficient,So Pump Have A Long Service Life Time.

2, It Is Easy To Install And Disassemble,And It Is Convenient To Maintain, Clean .There Is Less Wearing Parts.

3, High Efficiency And Energy Saving, Stable Transportation, Low Failure Rate, No Leak Sealing And Low Noise.

4, The Viscosity Of The Transportable Medium Is ≤2000000 Cp, And The Pump Can Transfer Slurry Containing 70% Solids.

5, It Can Transport Gas, Liquid And Solid Three-Phase Mixture Materials.

6, With Vfd, The Flow Can Be Adjusted At Will, And The Pump Can Be Used As A General Metering Pump.

7, If Need,We Can Do The Pump With Heating Jacket.

8, Applicable Temperature: -50 °C -250 °C.

9, Types Of Inlet/Outlet Connection: Flange Joint,Threaded Connection; Quick Connection.

10,Seal Type: Mechanical Seal And Packing Seal.

Lobe Pump Scope Of Application

Food: Wine, Olive Oil, Vegetable Oil, Molasses, Pressed Olive Waste, Fermented Grapes, Glucose, Tomato Concentrate, Chocolate. Industrial: Sludge, Slurries, Manure, Effluent, Crude Oil, Glue, Inks, Paint, Fuel oil, Mining: Bentonite, Ceramic Slips, Calcium Carbonate. Oil & Gas: Seawater, Crude-Oil products, Oily Sludge, Marine spills, Mud. Pharmaceutical: Detergents, Surfactants, Glycerine Wastewater: Membrane Bioreactor Filtration (MBR), Effluent, Sewage,

Relevant Machine