Automatic Capping-screw Cap-loading Cap-press Machine (Full-auto & Semi-auto & Manual Type)

Machine Working Video

Showroom Video

Product Introduction

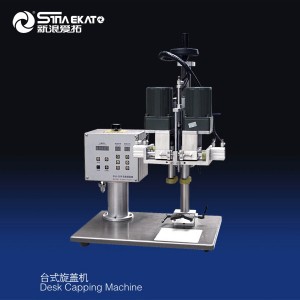

Automatic screw cap machine with automatic caps feeding is the latest improvement of a new type of capping machine. Aircraft elegant appearance, smart, capping speed, high pass rate, applied to food, pharmaceutical, cosmetic, pesticides, cosmetics and other industries of different-shaped screw-cap bottle.

Four speed motors are used for cover, bottle clip, transmit, capping, machine high degree of automation, stability, easy to adjust, or replace the bottle cap when not spare parts, just make adjustments to complete.

This full automatic capping machine is equipped with a cap feeder, which can orient bottle caps. Typically the cap feeder can be customized by making adjustments to the bowl for different sizes of caps. Larger caps and higher speeds may require larger bowls. These two machine can achieve automatically feeding caps and cap bottles, save labor and reduce production error.

With bottle cap feeder which can feed lids before capping bottle. This one needs to be customized according to cap size.

Equipped with a cap feeder, it will automatically feed bottle caps and tighten caps accurately. Improve production quality.

Suitable for different kinds of bottle caps. The capping time, pressing time can be adjusted by operation panel.

Intelligent operation panel and is with English version, can control working time and set working mode. With Stop button, can protect the machine from damage and keep the operator safe during working. The suitable transfer speed is set previously, but customer can adjust it if they need to do this.

Features

1.This screw capping machinery Suitable for automatic capping in cosmetic, medicine and drink, etc.

2.Good looking, easy to operate

3.Wide range of applications.

Specification

Can be customized

| No | Item | Data |

| l | Bottle height | 50-300mm(adjustable) |

| 2 | Cap diameter | 15-65mm(adjustable) |

| 3 | Speed | 40-50b/min |

| 4 | Control | PLC touch screen |

| 5 | Conveyor length | 2M |

| 6 | Pneumatic component | AIRTAC |

CE Certificate

Relevant Machine

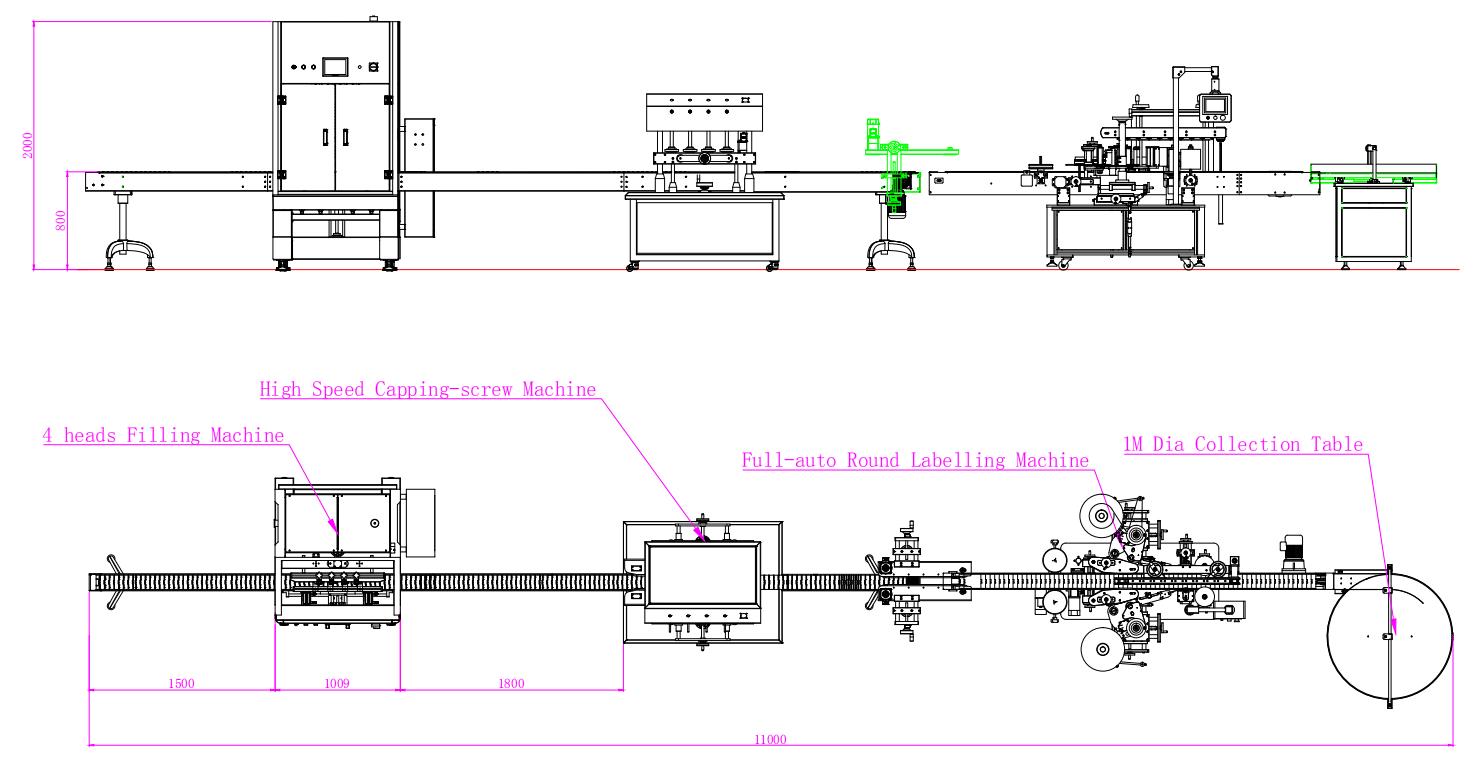

(Flowchart: Feeding table - Filling Machine - Cap-loading Machine - Cap-screw Machine - Labeling Machine - Ink Printer Machine - Collection Table)