Fixed Type Bottom Homogenizetr Vacuum Emulsifying Mixer Face Body Cream Lotion Homogenizing Machine

Machine Video

Application

| Daily cosmetic | |||

| hair conditioner | facial mask | moisturizing lotion | suncream |

| skin care | shea butter | body lotion | sunscreen cream |

| cream | hair cream | cosmetic paste | BB Cream |

| lotion | face wash liquid | mascara | foundation |

| hair color | face cream | eye serum | hair gel |

| hair dye | lip balm | serum | lip gloss |

| emulsion | lipstick | highly viscous product | shampoo |

| cosmetic toner | hand cream | shaving cream | moisturizing cream |

| Food&Pharmaceutical | |||

| cheese | milk butter | ointment | ketchup |

| mustard | peanut butter | mayonnaise | wasabi |

| toothpaste | margarine | Salad dressing | sauce |

Performance&Features

1. The mixing systems double-way mixing & helical ribbon mixing.

This agitator consists of two helical-shaped ribbons that are paired and rotate in opposite directions. It has the following characteristics: Efficient Mixing: The double helix design of the ribbon blades ensures efficient mixing of materials while avoiding dead spots, High Viscosity Handling: This type of agitator is particularly suitable for processing high viscous materials, such as adhesives, pastes, and gels educed Shear: The gentle mixing action of the ribbon blades reduces the shear that can occur in other types of mixers.

2. The triple mixing adopts the imported frequency converter for speed adiustment. which can meet different technological demands.

3. The homogenizing structure made through German technology adopts the imported double-end mechanical seal effect. The maximum emulsifying rotation speed can reach 3000 rpm and the highest shearing fineness can reach 0.2-5 u m.The vacuum defoaming can make the materials meet the requirement of being aseptic.

4. The machine uses an internal circulation system to achieve a more uniform and fine emulsifying effect. The material is circulated within the machine, undergoing multiple cycles of emulsification, until the desired consistency is achieved.

5. The vacuum material sucking is adopted, and especially for the powdelmaterials,vacuum sucking can avoid dust. The pot body is welded by imported three-layer stainless steel plate.

6. The tank body and the pipes adopt mirror polishing, which fully conforms to GMP requirements. According to technological requirements, the tank body can heat or cool the materials.

7. The heating modes mainly include steam heating or electric heating. To ensure the control of the whole machine is more stable, the electric appliances adopt imported configurations, so as to fully meet the international standards.

8. Easy to Clean and Maintain: The fixed pot body design makes it easy to clean and maintain the machine. This reduces the risk of contamination during the mixing process. The machine equipped with CIP, which can convinient user’s own CIP system to clean the machine.

9. The Siemens PLC control cabinet & Siemens touch screen To ensure the control of the whole machine is more stable,the electric appliances adopt imported configurations,so as to fully Easy-to-use control panel: The machine features a user-friendly control panel, which allows operators to easily adjust the speed, temperature, and other parameters as needed.

Technical Parameter

| Model | Capacity(L) | Mixing Power(KW) | Mixing Speed(r/min) | Homogenizer Power(KW) | Homogenizing Speed | Heating Method | Limit Vacuum(Mpa) |

| SME-DE 50L | 50L | 1.5KW | 0-63RPM | 3KW | 0-3000RPM | Electric heating or steam heating | -0.09 |

| SME-DE 100L | 100L | 2.2KW | 0-63RPM | 4KW | 0-3000RPM | Electric heating or steam heating | -0.09 |

| SME-DE 200L | 200L | 3KW | 0-63RPM | 5.5KW | 0-3000RPM | Electric heating or steam heating | -0.09 |

| SME-DE 300L | 300L | 3-5.5KW | 0-63RPM | 11KW | 0-3000RPM | Electric heating or steam heating | -0.085 |

| SME-DE 500L | 500L | 4-7.5KW | 0-63RPM | 15KW | 0-3000RPM | Electric heating or steam heating | -0.08 |

| SME-DE 1000L | 1000L | 7.5KW | 0-63RPM | 15KW | 0-3000RPM | Electric heating or steam heating | -0.08 |

| SME-DE 2000L | 2000L | 11KW | 0-63RPM | 18.5KW | 0-3000RPM | Electric heating or steam heating | -0.08 |

| Note : In case of inconformity of the data in the due to technical improvement or customization, the real object shall prtvail | |||||||

| Specification | |

| SME-DE Vacuum homogenizing emulsifying machine | |

| Capacity | 10-2000L |

| Uasage | Cosmetic cream,paste,ointment, lotion,gel,conditioner,milk,sauce |

| High shear rate | less than 2um |

| Contact part | SS316L(three jackets.contact material parts adoptSS316L, The rest are ss304 |

| Homogenizer speed | 0-3000rpm |

| Scraper speed | 0-63rpm |

| Heating | steam/electric |

| Operating | PLC |

| Type | 1. Lift type (Hydraulic lifting system) |

| 2 .Fixed type(the cover can't lift) |

Product Detailed

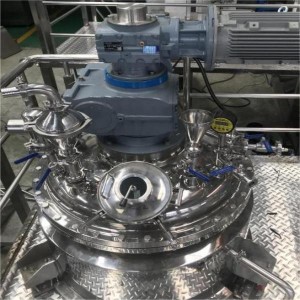

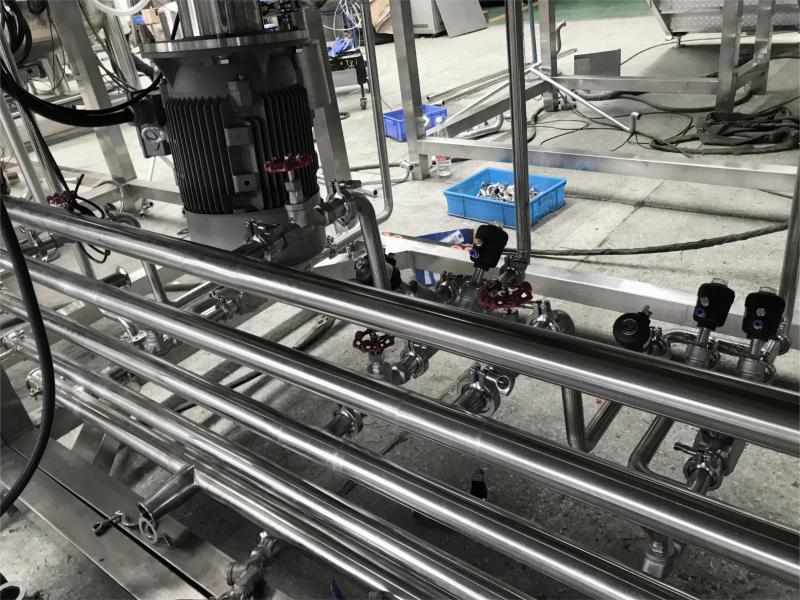

SME-DE Vacuum Emulsifying Mixer Project production

Oil Tank

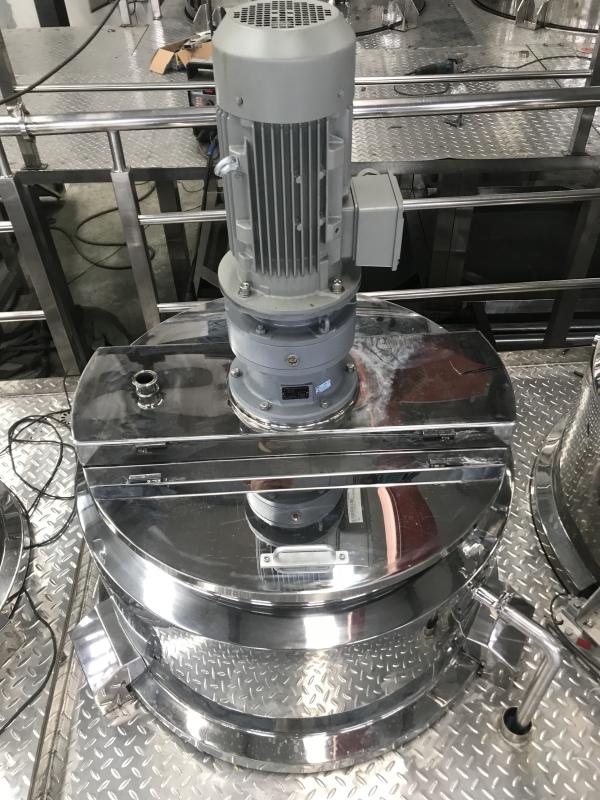

Double-way Mixing & Helical Ribbon Mixing

Bottom Homogenizer with Internal Circulation

PLC Control Electric Cabinet

Simone Touch Screen

Control Dial

Siemens Frequency Converter

Schneider Electric

Siemens s7-200 Smart(PLC)

Packing And Shipping

Company Profile

With the solid backing of Jiangsu Province Gaoyou City Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKATO Chemical Machinery Co., Ltd. is a professional manufacturer of various types of cosmetic machinery and equipment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, food, chemical industry, electronics, etc., serving many nationally and internationally famous enterprises such as Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., Ltd., Liangmianzhen Group, Zhongshan Perfect, Zhongshan Jiali, Guangdong Yanor, Guangdong Lafang, Beijing Dabao, Japan Shiseido, Korea Charmzone, France Shiting, USA JB, etc.

Project

Cooperative client

Our Service:

The delivery date is only 30 days

Customized plan according to requirements

Upport video inspection factory

Equipment warranty for two year

Provide equipment operation video s

Upport video inspect the finished product

Material Certificate

Contact person

Miss Jessie Ji

Mobile/What’s app/Wechat: +86 13660738457

Email: 012@sinaekato.com

Official Website: https://www.sinaekatogroup.com