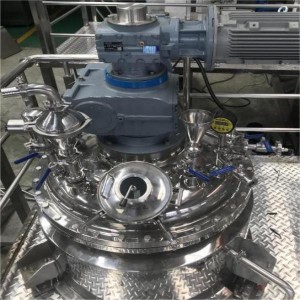

Electronic Control Top Homogenizer Bidirectional Mixing Vacuum Emulsifying for Cream Lotion Skincare Cosmetic Machinery

Production Video

Product Introduction

1. High speed rotor endows the material with high centrifugal speed and great centrifugal force. When slowing down instantaneously, the material suffers the associative action of cavitation, detonation, shearing and grinding. Meanwhile, the material is imbibed from upside of the homogenizer and erupted from the sideward plug hole. By the combined action of the stirrer along the vessel wall, granule spreads homogeneously and uniformly and the degree of uniformity shall come up to more than 99%.

2. Very small aperture between stator and rotor shall assure the effect of grinding, shearing, mixing and emulsifying of the material and avoid colliding and friction during the rotor rotates with high speed.

Technical Parameter

| Model | Capacity | Homogenizer Motor | Stir Motor | Dimension | Total Power | Limit vacuum(Mpa) | |||||

| KW | r/min | KW | r/min | Length(mm) | Width(mm) | Height(mm) | Steam heating | Electric heating | |||

| SME-C5 | 5L | 0.37 | 3000 | 0.18 | 63 | 1260 | 540 | 1600/1850 | 2 | 5 | -0.09 |

| SME-C10 | 10L | 0.75 | 3000 | 0.37 | 63 | 1300 | 580 | 1600/1950 | 3 | 6 | -0.09 |

| SME-C50 | 50L | 3 | 3000 | 1.1 | 63 | 2600 | 2250 | 1950/2700 | 9 | 18 | -0.09 |

| SME-C100 | 100L | 4 | 3000 | 1.5 | 63 | 2750 | 2380 | 2100/2950 | 13 | 32 | -0.09 |

| SME-C200 | 200L | 5.5 | 3000 | 2.2 | 63 | 2750 | 2750 | 2350/3350 | 15 | 45 | -0.09 |

| SME-C300 | 300L | 7.5 | 3000 | 2.2 | 63 | 2900 | 2850 | 2450/3500 | 18 | 49 | -0.085 |

| SME-C500 | 500L | 11 | 3000 | 4 | 63 | 3650 | 3300 | 2850/4000 | 24 | 63 | -0.08 |

| SME-C1000 | 1000L | 15 | 3000 | 5.5 | 63 | 4200 | 3650 | 3300/4800 | 30 | 90 | -0.08 |

| SME-C2000 | 2000L | 15 | 3000 | 7.5 | 63 | 4850 | 4300 | 3800/5400 | 40 | _ | -0.08 |

| Note: In case of inconformity of the data in the table due to technical improvement or customization,the real object shall prevail | |||||||||||

Applicable

|

Daily cosmetic |

|||

|

hair conditioner |

facial mask |

moisturizing lotion |

suncream |

|

skin care |

shea butter |

body lotion |

sunscreen cream |

|

cream |

hair cream |

cosmetic paste |

BB Cream |

|

lotion |

face wash liquid |

mascara |

foundation |

|

hair color |

face cream |

eye serum |

hair gel |

|

hair dye |

lip balm |

serum |

lip gloss |

|

emulsion |

lipstick |

highly viscous product |

shampoo |

|

cosmetic toner |

hand cream |

shaving cream |

moisturizing cream |

|

Food&Pharmaceutical |

|||

|

cheese |

milk butter |

ointment |

ketchup |

|

mustard |

peanut butter |

mayonnaise |

wasabi |

|

toothpaste |

margarine |

Salad dressing |

sauce |

Product Details

The homogenizing stirring system of SME-C bidirectional stirring vacuum emulsifier is composed of high-speed homogenizer shear, center stirring paddle and scraping stirring frame. High shear homogenizer can quickly refine the material. When it comes to sticky products, the stirring function of the single homogenizer is not so significant, but with the center mixing and box scraping of two-way mixing, the high-speed shear of the homogenizer can be faster and more efficient, and the full volume of materials can be quickly stirred without dead corners.

Shape of the Blender Blades: Two -way mixing with frame scraping wall Button Controlled: Each button has it own function, adjust mixing speed, etc

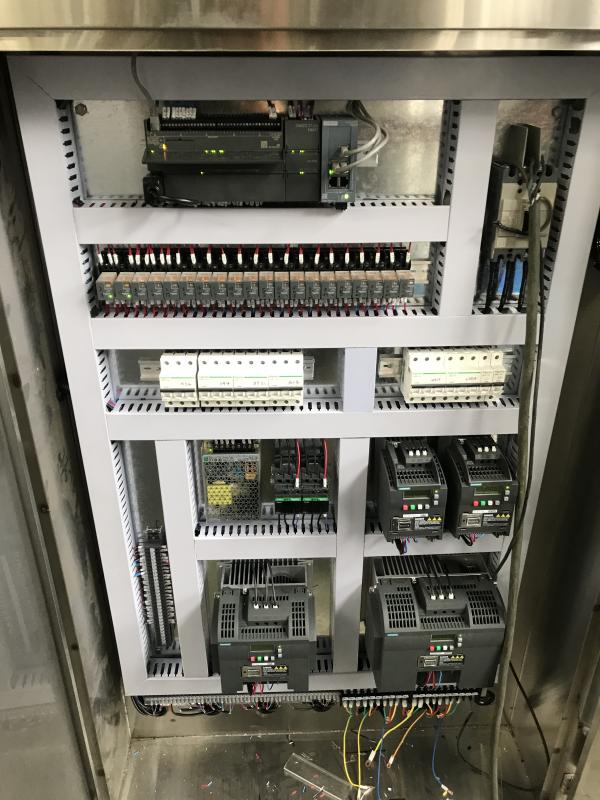

PLC control electric cabinet (clear line layout,high performance)

Cover parts(pressure meter, sight glass lamp, suck material inlet,manhole, etc)

Relevant Machines

We can offer machines for you as following

Reverse osmosis water purifier, vacuum homogenizing emulsifier. aseptic storage tank, drying sterilizer, ointment filling machine. conveving workbench, code printer,labeling machine, aluminumfoil sealing machine, shrink film machine

Click the picture to jump to the link related to the product

Fully automatic production line

Factory production

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Cooperative client

Material Certificate

Contact person

Miss Jessie Ji

Mobile/What’s app/Wechat: +86 13660738457

Email: 012@sinaekato.com

Official website: https://www.sinaekatogroup.com