Customized Pot Movable Emulsifier Homogenizer Vacuum Emulsifying Mixer Cosmetic Making Machine for Cream Lotion Skincare

Production Video

Product Introduction

Vacuum emulsifying machine is an ideal option to produce high-grade skin care products, pharmacy ointment, and many other kinds of creams which need to be very soft and smooth. It has the functions of heating, mixing, scraping, rotating at different speeds and vacuum supply. It has a very wide application from cosmetics (skin cream, hair gel, lotion etc) and food (jam, chocolate, sauces etc.) to pharmacy (ointment, syrup, paste) and chemicals(painting, adhesives, detergents)

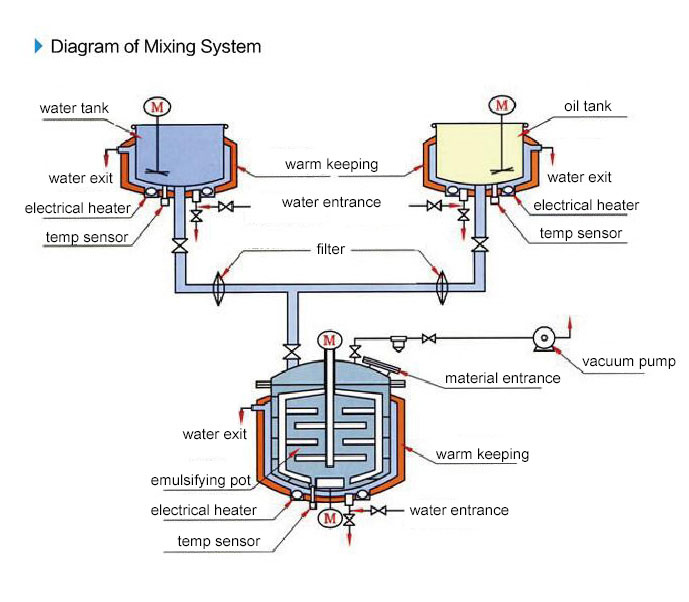

The machine is mainly made up of oil tank, water tank, vacuum homogeneous tank (main tank), heating system, mixing system, vacuum system, electric lifting system, operation control cabinet and piping system.

1. Provided with oil pressure lifting system, which can freely lift and lower the boiler cover and has such functions as boiler tilting.

2. The blending system adopts advanced triple blending and frequency conversion speed adjustment, so ads to satisfy production of different technology requirement.

3. Advanced homogenizer with unique structure and reliable sealing (the mechanical seal adopt Germany Bergman product), and the emulsifying rotation speed of 0-3500 rpm (Taiwan’s teco frequency debugger)

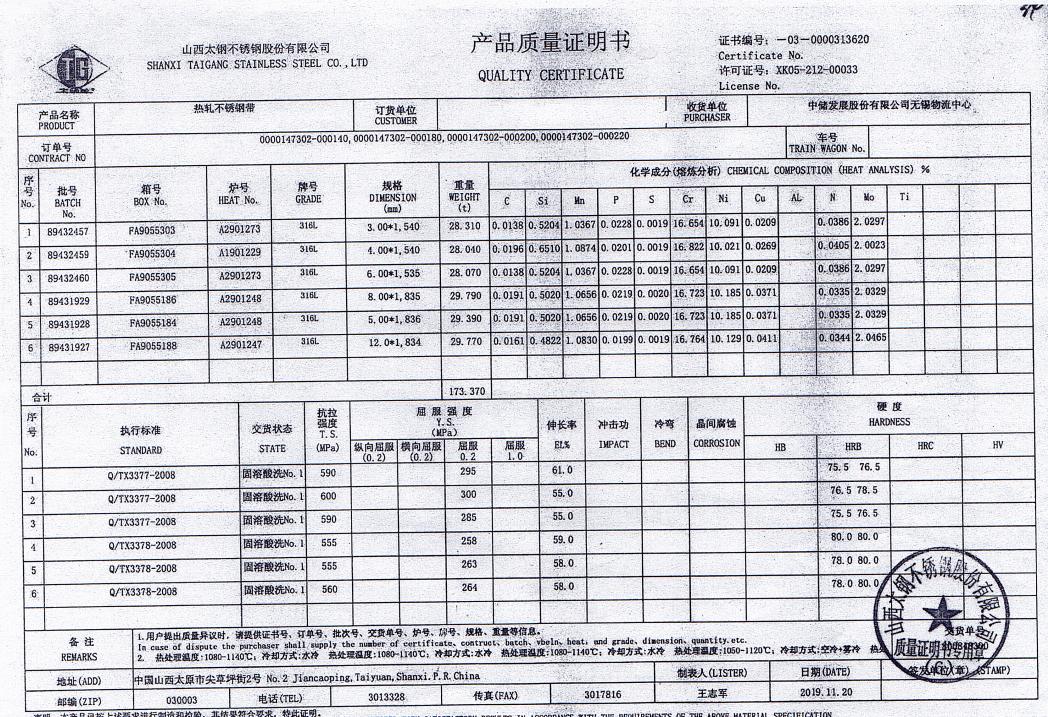

4. Made of imported SUS304 or SUS316L stainless steel. The tank body and pipe are carried out mirror polishing, which is in complete accordance with GMP standard.

5. The vacuum defoaming can make the materials meet the requirement of being sanitary and aseptic. The vacuum sucking material adopted can avoid dust, especially for the powder products.

Application

Machine Photo

Stainless Steel 316L Material Certificate

Parts we use

Service

Warranty time: one year, from the date which the product is qualified commissioning. Any damage except the wrong operation during warranty period is repaired freely. But the travel and hotel expenses should be count on buyer.

Commissioning services: the product's installation and commissioning at the demand side, our engineers will not leave there untill get your agreement.

Training services: our engineers will train your staff to operate it during the period of installation and commissioning, and they will not leave there until your staff can operate it properly and normally.

Maintenance services: any malfunction happened, once you enquiry us, we will reply you within 48 hours except the special reasons.

Lifelong services: we provide lifelong services for all the products we sold out, and supply the spare parts with discount price.

Certificate services: we can provide related certificates to customers freely according to the request of customers.

Inspection services: you can ask the third part inspection company or your inspector to inspect the products before shipment.

The file: the Manual Specification, report of the material which used to the equipment and others documents related to the GMP authentication information will be provided by us.

Our Team

Cooperative Customer