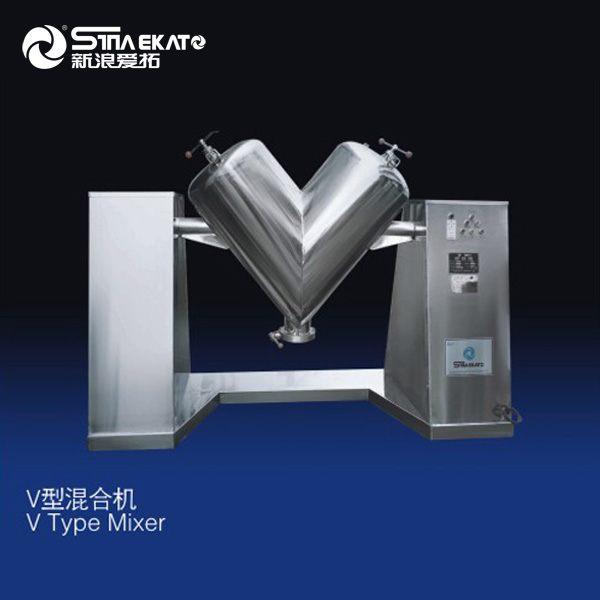

Stainless steel mixer Cosmetic Industrial trough type blender machine Spice powder mixer

Machine Video

Application

1.Mixing of the previous steps in the production of tablets and granules in the pharmaceutical industry.

2.Mixing of the food industry, such as condiments, dairy products, spices, cakes, etc.

3.Mix of feed production.

4.Mixing of powders and liquids in the chemical industry.

Performance & Features

1. This machine uses two motors, a stirring motor, which drives the mixing paddle to rotate the mixture material through the shaft. A discharge motor can be used to tilt the stirring tank to facilitate unloading.

2. There are one-way thrust ball bearings and radial thrust ball bearings at both ends of the stirring shaft to prevent radial turbulence caused by negative stress.

3. The sealing at both ends of the mixing shaft has been improved, and it can be completely sealed without contaminant material.

4. When jogging is used, it is easy to discharge, and it will not cause the phenomenon that the hopper tilts too much. The left end of the machine rotates. Because the worm wheel and the worm drive have self-locking effect, the mixing box can be dumped at any angle. .

5. Add the raw material to the cylinder at one time, dry it for a period of time, add the adhesive or spray the liquid, or add the raw material and the adhesive to the working container at one time, and mix it into the ideal soft material.

Technical Parameters

| Model | 50L | 300L | 550L |

| Blades form | S type paddle | S type paddle | S type paddle |

| Volume(L) | 50 | 300 | 550 |

| Agitation speed(r/min) | 24 | 24 | 24 |

| Flip Angle | < 105 | < 105 | < 105 |

| Mixing motor(kW) | 1.5 | 5.5 | 7.5 |

| Dumping motor(kW) | 0.37 | 1.1 | 1.5 |

| Dimension(mm) | 1200*500*950 | 2150*700*1250 | 2400*1000*1300 |

| Weight(kg) | 200 | 550 | 850 |

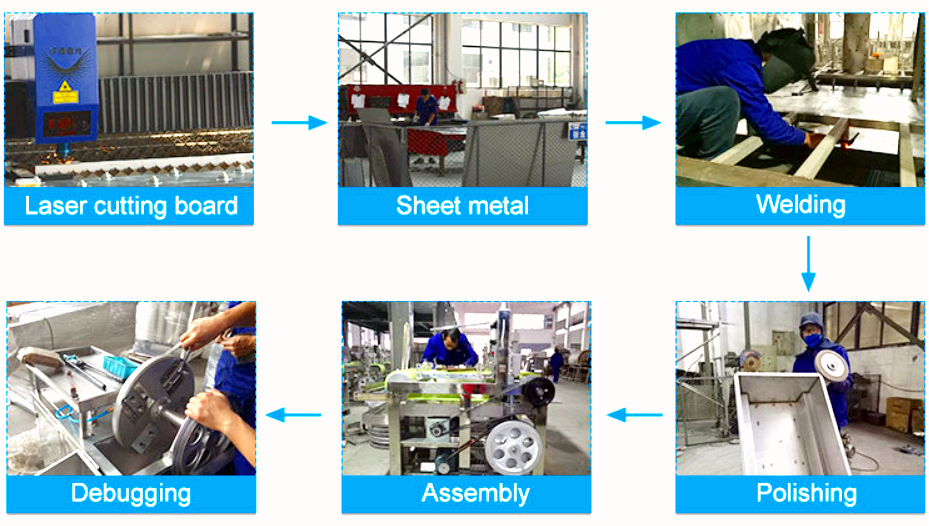

Production Flow Line

Company Profile

With the solid backing of Jiangsu Province Gaoyou City Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKATO Chemical Machinery Co., Ltd. is a professional manufacturer of various types of cosmetic machinery and equipment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, food, chemical industry, electronics, etc., serving many nationally and internationally famous enterprises such as Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., Ltd., Liangmianzhen Group, Zhongshan Perfect, Zhongshan Jiali, Guangdong Yanor, Guangdong Lafang, Beijing Dabao, Japan Shiseido, Korea Charmzone, France Shiting, USA JB, etc.

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Company Profile

Cooperative Client

Our Service:

The delivery date is only 30 days

Customized plan according to requirements

Upport video inspection factory

Equipment warranty for two year

Provide equipment operation video s

Upport video inspect the finished product

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/What’s app/Wechat: +86 13660738457

Email: 012@sinaekato.com

Official website: https://www.sinaekatogroup.com