Mobile High shear emulsifying

Machine Video

Performance & Features

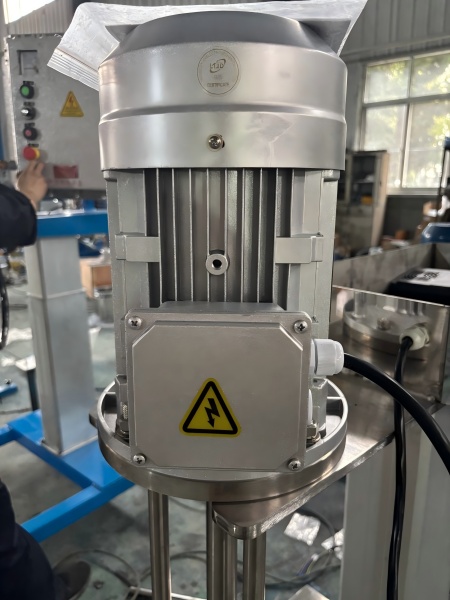

| Equipment parameter: | |

|

Power source |

380V/50HZ/60HZ |

|

Drive |

Three-phase asynchronous motor |

|

Lifting method |

Up and down lifting, stable operation, lifting stroke 700mm, electric aluminum lifting platform. |

|

Processing capacity |

50 - 100L, with water as the medium. |

|

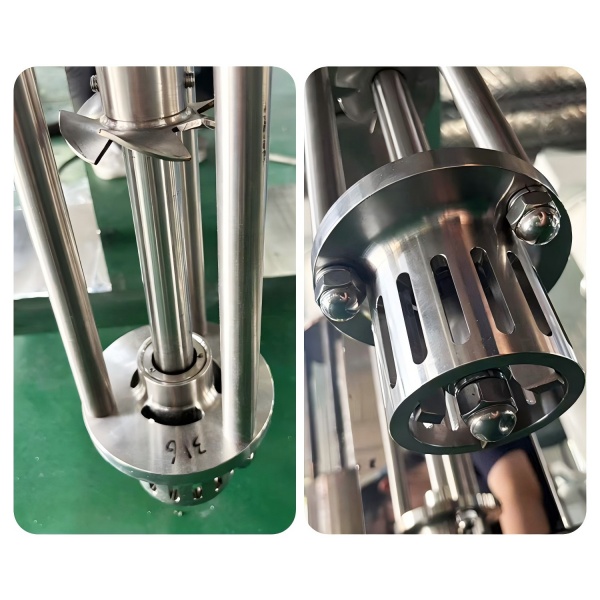

Emulsifying head |

Detachable fine-pore emulsifying head with a lower-pressing type dispersion disc in the middle, made of 316 stainless steel. |

|

movable |

The bottom of the machine is equipped with four 2.5-inch swivel casters. |

|

Stirring motor power |

0.75KW/1.5KW/2.2KW/4KW/5.5KW/7.5KW(Customization is available according to customer requirements.) |

|

Stirring speed range |

0-2800Rr/min,Variable frequency speed regulation, with real-time display of voltage, current and rotational speed. |

Working principle

The high-shear dispersing emulsifier consists of one or several sets of high-speed rotating rotors and stators. The high-speed rotating rotor draws materials from the bottom of the container into the rotor area, where the materials are subjected to intense mixing and shearing. Forced through the precisely matched gap between the stator and rotor, the materials are ejected from the tooth gaps of the stator. During this process, they undergo severe mechanical and liquid shearing, which tears and crushes the particles. At the same time, new materials are sucked into the center of the rotor, and the ejected materials change direction at the container wall before re-entering the rotor area to be sheared again. This ensures that the materials are thoroughly refined, homogenized, and dispersed, achieving the optimal shearing effect.

Technical Parameter

In the world of industrial mixing and emulsification, the high shear emulsifier stands out as a vital piece of equipment. Designed to create stable emulsions and finely dispersed mixtures, these machines are essential in various industries, including food, pharmaceuticals, cosmetics, and chemicals. With advancements in technology, the latest models of high shear emulsifiers offer enhanced features, including customizable power options and variable speed settings, making them suitable for a wide range of applications.

One of the most significant advantages of modern high shear emulsifiers is their customizable power options. Available in power ratings of 1.5KW, 2.2KW, 4KW, 5.5KW, and 7.5KW, these machines can be tailored to meet the specific needs of different processes. Whether you are working with small laboratory batches or large-scale production, there is a high shear emulsifier that can accommodate your requirements. The ability to select the appropriate power level ensures optimal performance, efficiency, and energy consumption.

Another key feature of high shear emulsifiers is their adjustable speed settings, which can range from 0 to 3000 rpm. This flexibility allows operators to fine-tune the mixing process according to the viscosity and characteristics of the materials being emulsified. For instance, lower speeds may be ideal for delicate emulsions, while higher speeds can be employed for more robust mixtures. This capability not only enhances the quality of the final product but also reduces the risk of damage to sensitive ingredients.

High shear emulsifiers come in various forms, each designed for specific applications. Some of the most popular types include:

1. Small Laboratory Vacuum Homogenizing Emulsifier: Ideal for research and development, this compact unit allows for precise emulsification in small batches, making it perfect for testing new formulations.

2. Mobile Emulsifying Grinder: Designed for flexibility, this portable emulsifier can be easily moved between different production areas, making it suitable for facilities with limited space.

3. High-Speed Homogenizer: This type of emulsifier is engineered for high-speed mixing, ensuring rapid and efficient emulsification of various materials.

4. Stainless Steel High-Shear Emulsifier: Constructed from high-quality stainless steel, this emulsifier is not only durable but also easy to clean, making it ideal for industries that require strict hygiene standards.

5. Hydraulic Lifting Emulsifier: Featuring a hydraulic lifting mechanism, this emulsifier allows for easy adjustment of the mixing head, accommodating different container sizes and ensuring optimal mixing conditions.

6. Pipeline Emulsifier: Designed for continuous processing, this emulsifier can be integrated into production lines, providing seamless emulsification without the need for batch processing.

7. Shear Pump: This innovative device combines the functions of a pump and a high shear emulsifier, allowing for efficient transfer and emulsification of materials in one step.

The high shear emulsifier is an indispensable tool in modern manufacturing, offering versatility, efficiency, and precision. With customizable power options and adjustable speed settings, these machines can be tailored to meet the unique needs of various industries. Whether you are looking to create stable emulsions in a laboratory setting or streamline production processes in a manufacturing facility, investing in a high shear emulsifier can significantly enhance your operations. As technology continues to evolve, these emulsifiers will undoubtedly play a crucial role in the future of mixing and emulsification processes.

Relevant Machines

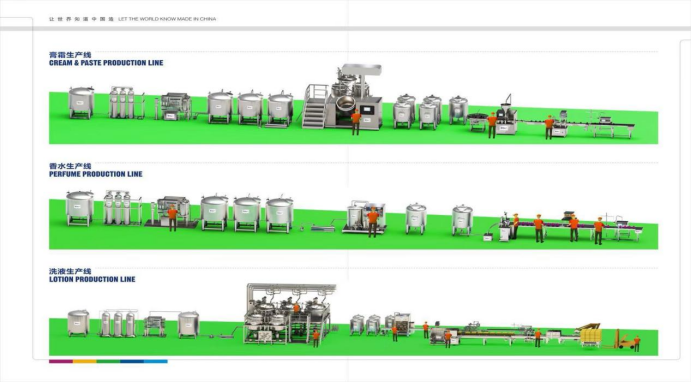

We can offer machines for you as following :

(1)Cosmetics cream ,ointment ,skin care lotion ,toothpaste production line

From Bottle washing machine -bottle drying oven -Ro pure water equipment -mixer -filling machine -capping machine -labeling machine -heat shrink film packing machine -inkjet printer -pipe and valve etc

(2)Shampoo,liquid saop ,liquid detergent(for dish and cloth and toilet etc ) ,liquid wash production line

(3)Perfume production line

(4)And other machines ,powder machines ,lab equipment ,and some food and chemical machines

Fully automatic production line

SME-65L Lipstick Machine

Lipstick Filling Machine

YT-10P-5M Lipstick Freeing Tunnel

FAQ

1.Q:Are you factory?

A: Yes,we are a factory with more than 20 years manufacturing experience.Welcome to visit our factory.Only 2 hour fast train from Shanghai Train Station and 30 minutes from Yangzhou Airport.

2.Q: How long is the machine warranty?After warranty, what if we meet problem about the machine?

A: Our warranty is one year.After warranty we still offer you lifetime after-sales services.Anytime you need, we are here to help. If the problem is easy to solve,we will send you the solution by email.If it doesn't work,we will send our engineers to your factory.

3.Q: How can you control the quality before delivery?

A:First,our component/spare parts providers test their products before they offer com- ponents to us, Besides, our quality control team will test machines performance or running speed before shipment.We would like to invite you come to our factory to verify machines yourself. If your schedule is busy we will take a video to record the testing procedure and send the video to you。

4. Q: Are your machines difficult to operate? How do you teach us using the machine?

A: Our machines are fool-style operation design,very easy to operate. Besides,before delivery we will shoot instruction video to introduce machines’ functions and to teach you how to use them. If needed engineers are available to come to your factory to help install machines.test machines and teach your staff to use the machines.

6.Q: Can I come to your factory to observe machine running?

A: Yes, customers are warmly welcome to visit our factory.

7.Q: Can you make the machine according to buyer's request?

A: Yes,OEM is acceptable. Most of our machines are customized design based on cus- tomer's requirements or situation.

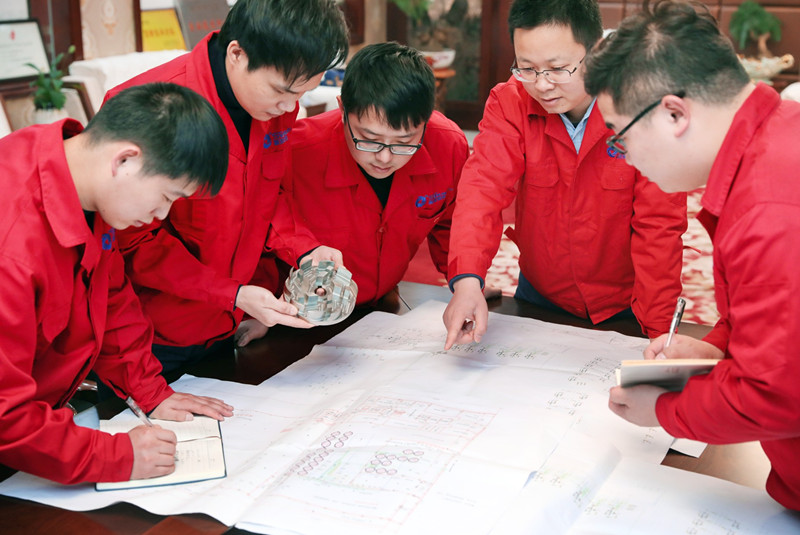

Company Profile

With the solid backing of Jiangsu Province Gaoyou City Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKATO Chemical Machinery Co., Ltd. is a professional manufacturer of various types of cosmetic machinery and equipment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, food, chemical industry, electronics, etc., serving many nationally and internationally famous enterprises such as Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., Ltd., Liangmianzhen Group, Zhongshan Perfect, Zhongshan Jiali, Guangdong Yanor, Guangdong Lafang, Beijing Dabao, Japan Shiseido, Korea Charmzone, France Shiting, USA JB, etc.

Exhibition Center

Company Profile

Professional Machine Engineer

Professional Machine Engineer

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Packing and Shipping

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/What’s app/Wechat: +86 13660738457

Email: 012@sinaekato.com

Official website: https://www.sinaekatogroup.com