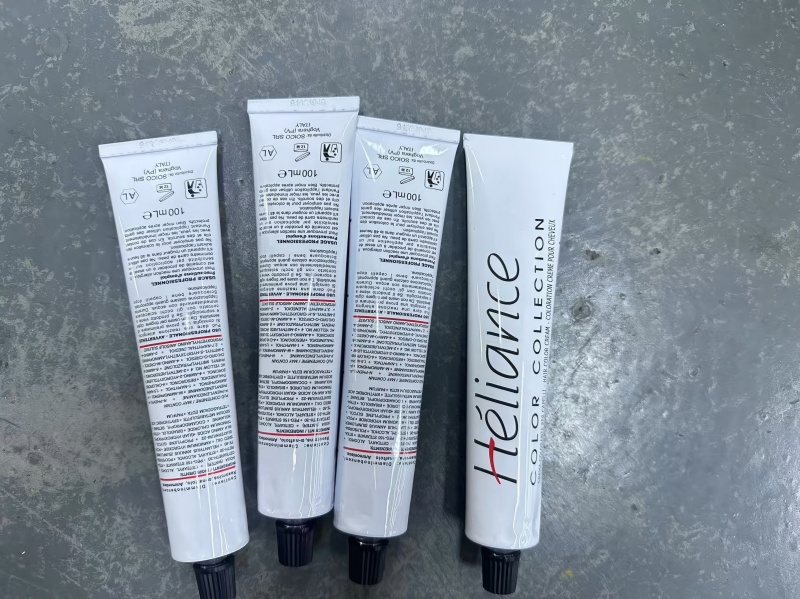

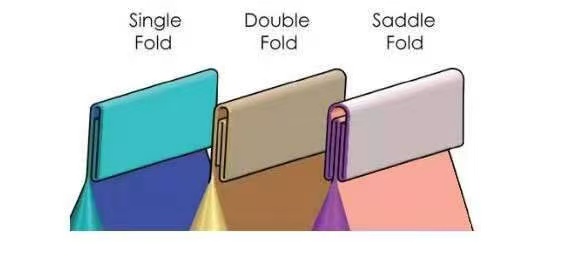

GFZ-L 80Pcs/New model-Aluminum tube double-fold tail sealing machine

Machine Video

Application

Features

Biggest Special:

Speed: 80Pcs/Min for 100ml tube;

New Model - Aluminum Tube Double Fold Sealing Machine: Combination of Efficiency and Precision

In the ever-evolving world of manufacturing and packaging, the introduction of advanced machinery is crucial for improving productivity and ensuring product quality. One such innovation is the new aluminum tube double-fold tail sealer, designed to meet the demands of modern production lines. With an impressive sealing speed of 80 pieces per minute, the machine is designed to optimize efficiency while maintaining the highest standards of precision.

1. Smart touch screen:

The new models feature an intelligent touchscreen interface for easy operation. This user-friendly feature allows operators with limited technical experience to easily navigate the various settings and functions. The intuitive design shortens the learning curve, enabling quick adaptation and minimizing downtime during production shifts.

2. Piston metering system:

A key feature of this sealer is its piston metering system, which ensures extremely high filling accuracy. This technology is crucial for industries such as cosmetics, pharmaceuticals, and food, which require precise metering. The piston metering system ensures that each tube is filled to exact specifications, reducing waste and improving product consistency.

3. No tube required, no filling required:

To further enhance operational efficiency, the machine incorporates a "no tube, no filling" mechanism. This prevents the machine from dispensing product without a tube, significantly reducing the risk of spillage and ensuring every drop of material is effectively utilized. This not only conserves resources but also streamlines production processes, making it more sustainable.

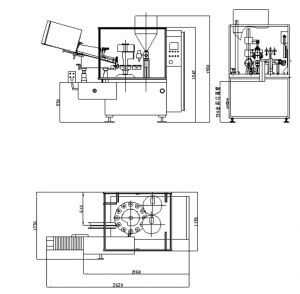

Technical Parameter

The product is suitable for automatic color code aligning, filling, sealing, date printing and end cutting of various plastic tubes and aluminum composite tubes. lt is widely applied in daily chemical industry, medicine, food, etc.

Features

1) High grade LCD programming controller and button combined operation video screen, fully grasp the equipment stepless speed regulation, parameter equipment, output count statistics, pressure indicator, faul display and other operating conditions, so that the operation is simple and user-friendly.

2) The whole process of fully automatic pipe supply, marking, inert temperature gauge (optional), filling folding, coding and finished products outlet.

3) High precision calibration system reduces the range of color difference between the tube body and the color standard.

4)External adjustment part, position digital display, quick and accurate adjustment (suitable for multi-specification, multi-variety production).

5) Integration of machine, light, electricity and air, no pipe without filling in the real column, the supply pipe is not in place, low pressure, automatic display (alarm); Open the protective door can stop automatically and other automatic functions.

6) If the rejection rate is not caused by the demander's pipes, the qualified rate of the equipment shall be above 99.5%.

|

Model |

GZF-L80 |

| Tube material |

Metal/Aluminum |

| Tube diameter |

10-32 |

|

Tube length |

45-250mm (can customized) |

|

Tube volume |

5-500ML/Piece (can adjust) |

| Tube precision |

±0.5% |

|

Productivity speed |

60-80Pcs/Min |

|

Compressed air |

France |

| Motor power |

2KW |

| Dimension(mm) | 2500*1200*2400mm |

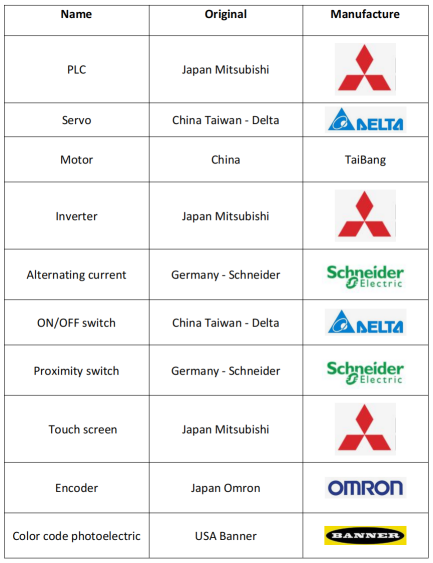

Machine configuration

GZF-S Semi-auto Cream Lotion Toothpaste Hair-dye Gel Tube Filling and Sealing Machine (Works for Plastic & Laminated & Aluminum Tube)

Exhibitions & Customers visit factory